Meeting and Managing

Using Lean Team Player, the geographically dispersed team members are able to meet virtually and plan the Shredder’s pivot to a pivoted board design in one space. Let’s see how they connect, contribute, and stay organized digitally.

3DEXPERIENCE Works Solution Utilized:

Pete kicks off the team’s virtual design meeting through the company’s collaborative dashboard. With Eric Engineer and Dan Designer both working remotely, Pete takes advantage of Lean Team Player to coordinate his team and capture action items from the brainstorm. Lean Team Player enables collaboration as the team takes on the remaining design challenges.

Designing Concurrently for Success

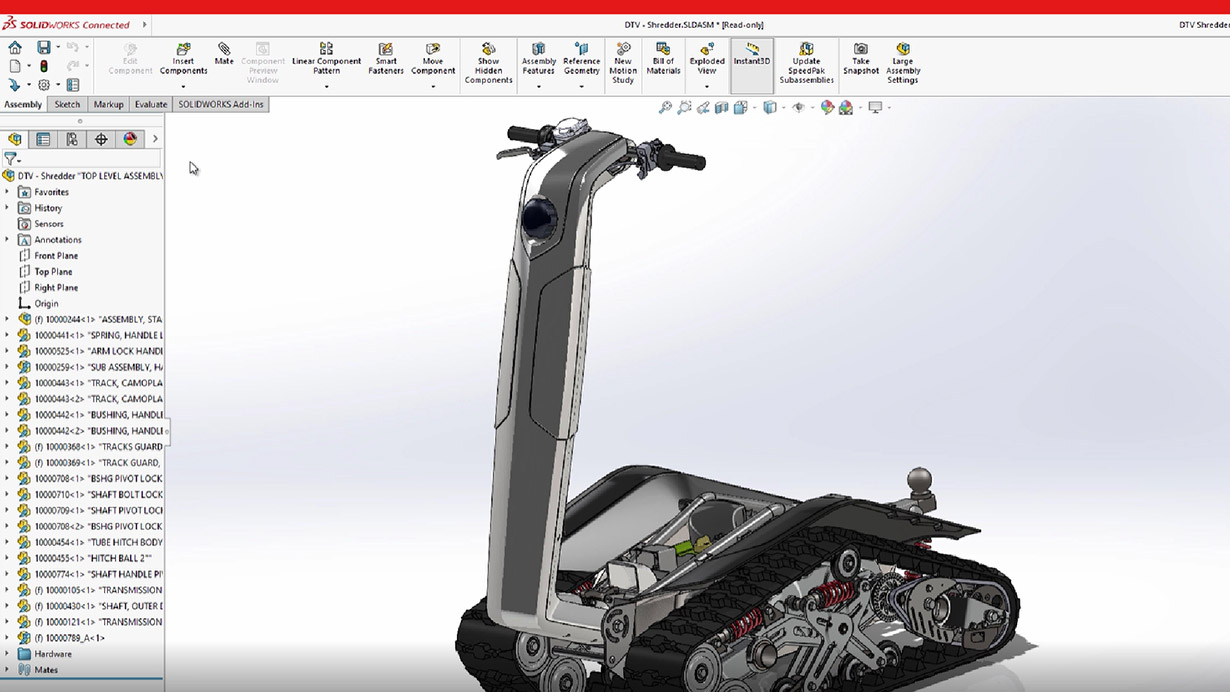

The tasks have been set and it’s time for the team to get to work creating a unique riding experience. The team’s designer takes on the new board design while the engineer cracks down on the new steering system. They are able to work quickly and simultaneously on the same model by reserving different parts and assemblies on the cloud. The new and improved Shredder design is moving along at a rapid clip!

3DEXPERIENCE Works Solution Utilized:

Shredder Videos

The rider platform design has been sketched out. Now it is Dan's turn to evolve a concept into a production ready part. Dan uses the surfacing capabilities within 3DEXPERIENCE SOLIDWORKS to create a new 'board' design. Manufacturing considerations, along with additional surface finishes, are also taken into consideration as Dan's design unfolds.

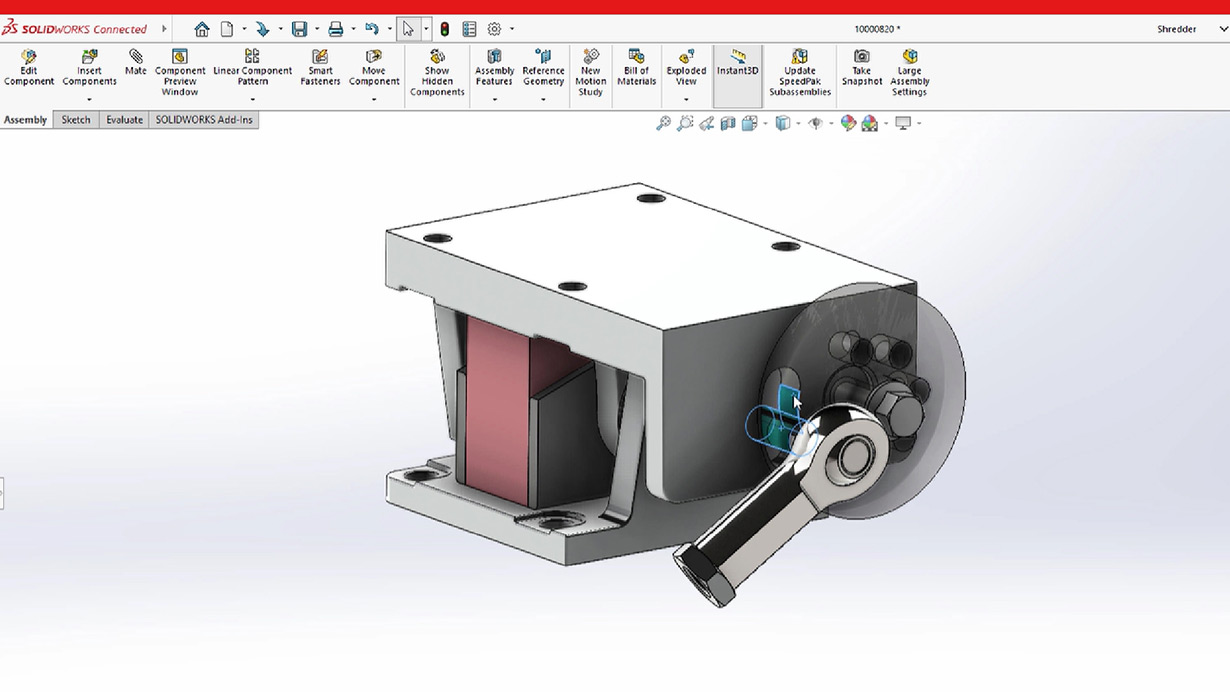

Eric's task of designing the new turning mechanism requires understanding kinematics of the rider platform and how it connects to the Shredders existing clutch system. Taking advantage of existing design data along with simple to use assembly motion inside of 3DEXPERIENCE SOLIDWORKS ensures Eric builds the most intelligent design, while keeping costs low and delivery on time.

The rider platform design has been sketched out. Now it is Dan's turn to evolve a concept into a production ready part. Dan uses the surfacing capabilities within 3DEXPERIENCE SOLIDWORKS to create a new 'board' design. Manufacturing considerations, along with additional surface finishes, are also taken into consideration as Dan's design unfolds.

Solving the Shredder

A design can look perfect, but nothing truly matters if it can’t perform as designed in the real world. See how the team’s resident engineer takes charge with simulation studies to get the new and improved Shredder design validated and ready for manufacturing.

3DEXPERIENCE Works Solution Utilized:

While designing the pivot and clutch mechanism, Eric comes across some concerns about the bushing. How do different materials and shapes change the overall riding experience? This is a perfect opportunity to virtually validate iterations utilizing the simulation capabilities of the 3DEXPERIENCE platform.

Working Together to Resolve Issues

The new design hits a snag when the team’s supplier spots an issue: with the new board design, the Shredder can no longer fold and lay flat for easy storage. How can everyone work together to identify and fix the problem? See how collaborating on the 3DEXPERIENCE platform saves the day.

3DEXPERIENCE Works Solution Utilized:

Sam runs across a concern on interference that was missed during the design phase. With a quick issue log on the 3DEXPERIENCE platform, the concern from Sam is clearly communicated to Pete, who takes action against the affected components and allows Dan to make the appropriate modifications.

Moving on to Manufacturing

With the design issue solved, it’s time to dive into the manufacturing process. Check out how cloud-connected manufacturing tools help bring a complex Shredder part to life.

3DEXPERIENCE Works Solution Utilized:

Finished Up with Time to Shred

With the entire team connected on a single platform, making changes to the design was smooth and easy. Learn how you too can finish up projects ahead of schedule and under budget with the power of 3DEXPERIENCE Works!